Tel: +86 18729482322

Whatsapp & Wechat: +86 18729482322

Skype:chengshirly@hotmail.com

E-mail:sales@manoinstrument.com

Website: www.manoinstrument.com

2017-04-131511 have been browsing

With the implementation of the strategic plan for Made in China 2025, and the continuous increase in labor costs. Industrial enterprises have stepped up efforts to improve intelligent manufacturing such as production automation, networking, and informatization. Pressure measuring instruments have also been upgraded from traditional instruments to digital, intelligent and Internet instruments. The user's demand for digital pressure gauges are increasing, and at the same time, more requirements are put forward in terms of performance and functions. Today Let’s take a deeper look at the digital pressure gauge.

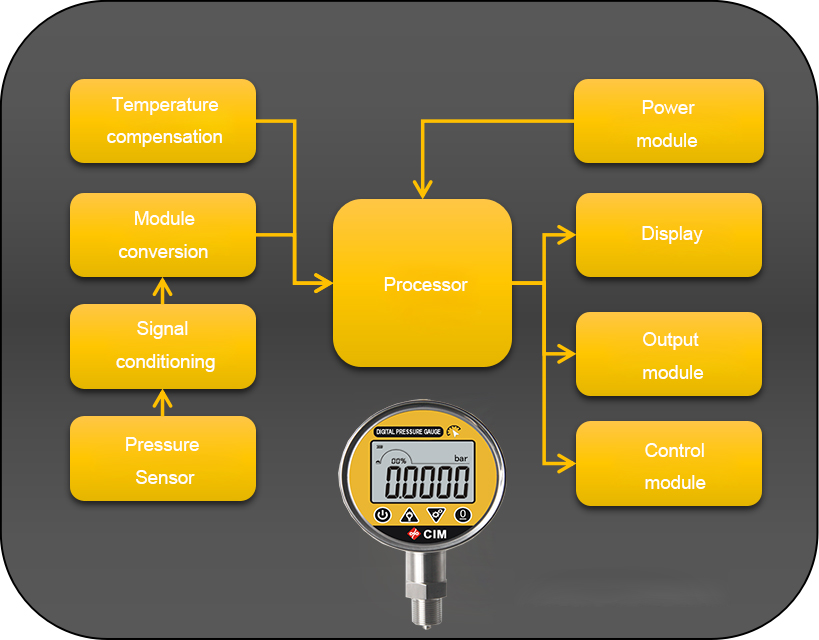

Working principle

Looking at the structure diagram above, do you think the structure of the digital pressure gauge still looks quite complicated? Then I will tell you how they work. First, the pressure sensor will produce the same proportion of electrical signal as the pressure changes. This signal is filtered and amplified by the signal conditioning section, and then converted into a digital signal by the analog-to-digital conversion section and sent to the processor. The processor calculates this signal and generates the corresponding pressure value after temperature compensation. The pressure value is displayed on the screen and converted to an analog signal through the output module (generally, 4~20mA or 0~5V, etc.) or digital signals (usually RS485 or RS232, etc.) are output to other external devices. The control module is used to output the switching value, and is generally used for upper and lower limit alarms, or for pressure control. It has the same function as the traditional electric contact pressure gauge.

Tips:

Temperature compensation: All electronic devices will have temperature drift, which will affect the accuracy of the pressure value. The temperature compensation circuit is used to eliminate the error caused by this temperature drift, so that the reading of the digital pressure gauge is more accurate. Traditional pointer pressure gauges also have temperature drift, but there is no function of temperature compensation for process reasons. Some digital pressure gauges do not have temperature compensation in order to save material costs and reduce the complexity of the production process, so everyone must carefully identify when selecting products and try to choose digital pressure gauges with temperature compensation.

Skype

Tel